Tire Uniformity Geometry Balancing Revolution

Is it a revolution or some kind of „mission impossible“? Does it really make sense to think about? How to save energy and cycle time in tire final finishing?

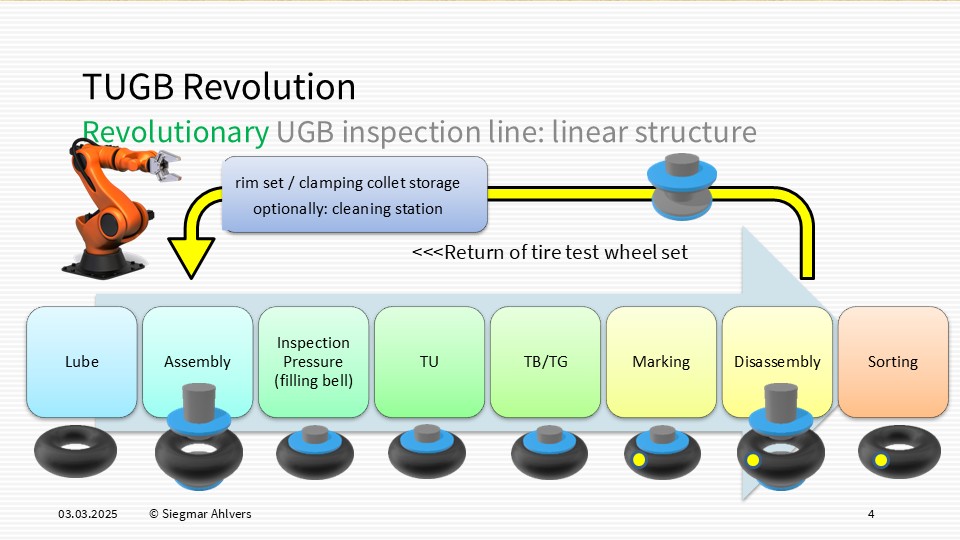

How to decrease cycle time from 28…24…20s to 16…14s.

My name is Siegmar Ahlvers. After my study as electrical engineer I have worked 37 years at a machine builder company in Hanover, Germany. We have supplied tire geometry and uniformity technology and machinery to the tireindustry worlwide. Today I „work“ more or less as an artist.

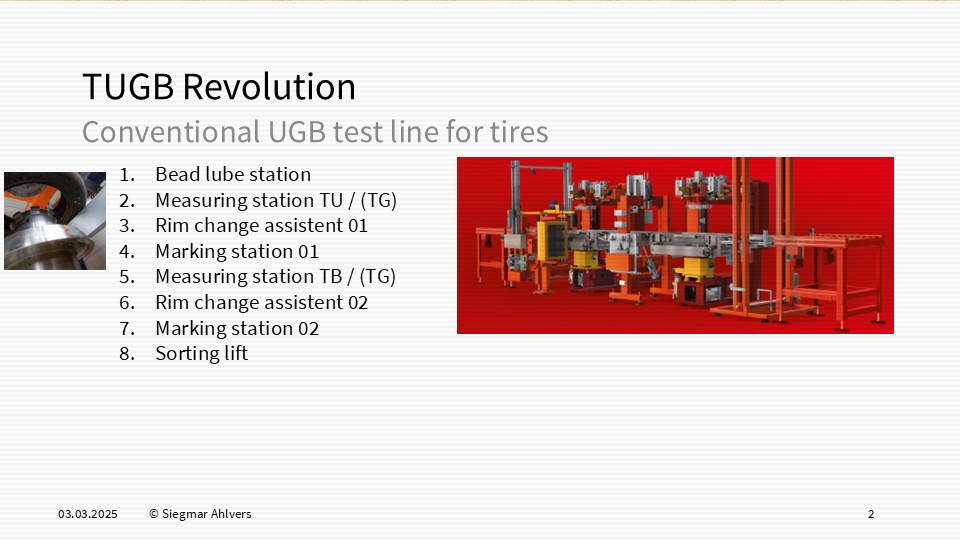

I assume that tire uniformity specialists know the principles of such force variation measurement machinery. Nevertheless, I assume that about 15…20 years ago I had the idea to replace a tire uniformity machine by some kind of „artificial tire wheel assembly“ uniformity machine. Why? To save energy for multiple tire inflation at seperated tire uniformity / geometry / balancing machines. And additionally to speed up the tire final finishing process by several seconds.

Here is my idea – currently in March 2025 – available as Powerpoint / PDF presentation. (German Versions [outdated]: PDF / PPT)

The revolutionary solution?

PS: which tire producer has tested such a concept until today?

Please let me know if you want.

I will visit TTE Tire Technology Expo 2025 in Hanover presumably at March 05. 25. In case of interest you can contact me by email siegmar@ahlvers.de or by Phone +1728738242. See you!